GREASOMATIC®96

SINGLE POINT AUTOMATIC LUBRICATION

The Greasomatic®96 is the only single point automatic lubricator manufactured in Great Britain.

What Is The Greasomatic®96

Greasomatic®96 single point automatic lubricators are the most cost-effective alternative to manual lubrication.

With over 50 years of experience Wymark Limited has learnt that in reality manual lubircation either doesn't get carried out enough or gets carried out too much. Both under and over lubrication cause premature bearing/machine failure.

Greasomatic®96 OPTIMUM LUBRICATION SYSTEM

The Greasomatic®96 supplies a continuous and precise volume

of lubricant providing optimum lubrication.

Benefits of Greasomatic®96 automatic lubrication

Manual/Grease Gun Lubrication

- No further need for costly time consuming manual lubrication.

- Labour saving/less labour intensive maintenance.

- Improved health and safety.

- Reduction in lubricant consumption.

- Lessen environment impact.

Asset Reliability/Care

- Reduced costly downtime and failures.

- Improved production performance.

- Extend asset life.

- Reduce maintenance costs.

Rationalise/Simplify

- Ensure the correct lubricant is being used in the correct quantity, in the correct place at the correct time.

- No more cross contamination of lubricants.

- No more ingress of contaminates into the application.

What Are The Advantages of Greasomatic®96 automatic lubrication

Greasomatic®96 single point automatic lubricators are the most cost effective alternative to manual lubrication. With over 50 years of experience Wymark Limited has learnt that in reality manual lubircation either doesn't get carried out enough or gets carried out too much. Both under and over lubrication cause premature bearing/machine failure.

HOW IT WORKS

Each GREASOMATIC contains its own unique chemical expulsion unit. This has no springs or mechanisms but relies on an unvarying law of nature.

Built into the top of each GREASOMATIC is a flexible rubber expansion chamber containing a liquid electrolyte and a galvanic element. The unit is activated by injecting the galvanic element into the electrolyte.

The resultant electro-chemical reaction generates a steadily increasing amount of gas, which gradually expands against a piston, to extrude the lubricant slowly but surely into the bearing to which the GREASOMATIC is fitted.

The chemicals and gas remain hermetically sealed within the expansion chamber so that no contamination of the lubricant can occur, even after the unit itself is spent.

During the working life of the GREASOMATIC, an indicating ring on the ejection piston shows through translucent windows in the body to enable the discharge state to be monitored.

THE PRESSURE RELIEF VALVE

This is provided to guard against the possibility of the GREASOMATIC being fitted unwittingly to a bearing with blocked greaseways.

Should the pressure built up by the GREASOMATIC prove insufficient to clear the blockage, the valve will open to allow the lubricant to escape and prevent excessive pressurisation of the GREASOMATIC.

The exudation of lubricant around the GREASOMATIC will serve as a warning that the greaseways are blocked and that no lubrication is taking place.

An unactivated GREASOMATIC

A working GREASOMATIC

What Are The Advantages of Greasomatic®96 automatic lubrication

Greasomatic®96 single point automatic lubricators are the most cost effective alternative to manual lubrication. With over 50 years of experience Wymark Limited has learnt that in reality manual lubircation either doesn't get carried out enough or gets carried out too much. Both under and over lubrication cause premature bearing/machine failure.

Applications & Industries

Greasomatic®96 is made with high-quality materials and is hermatically sealed meaning it can withstand the harshest of environments, even underwater.

Automatically delivering lubricant in the simplest, most efficient and most economical way.

- Pumps & compressors

- Oil refineries/Rigs

- Underground & surface mining

- Quarries

- Pulp & paper mills

- Crushers & shakers

- Air handling equipment

- Food & beverage processing

- Power generating stations

- Bridge & stacker cranes

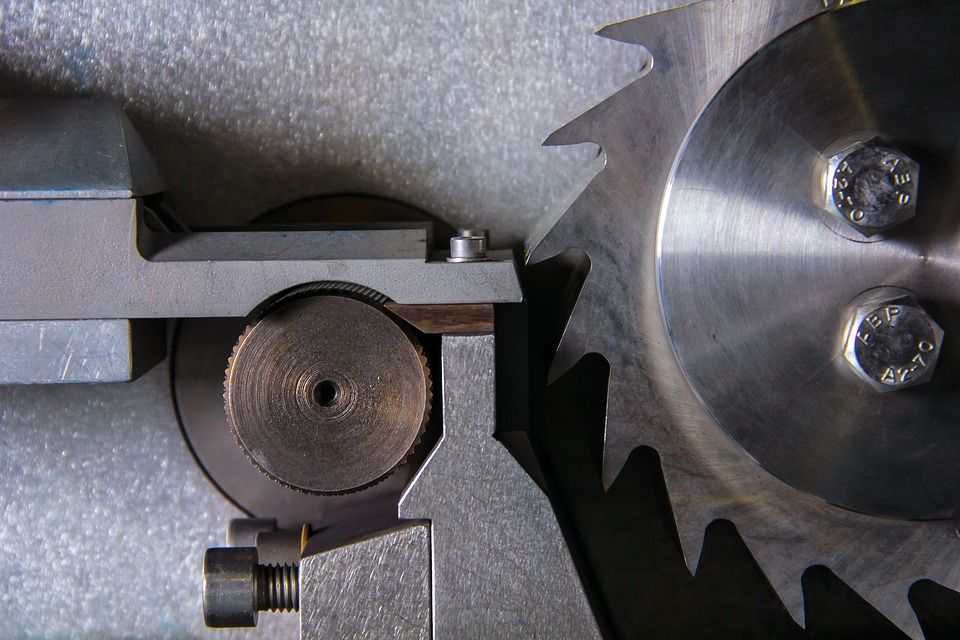

- Sawmills

- Pharmaceutical plants

- Foundries

- Textile producers

- Glass industries

- Airports

- Plastic moulders

- Steelworks

- Automotive assembly

- Cement plants

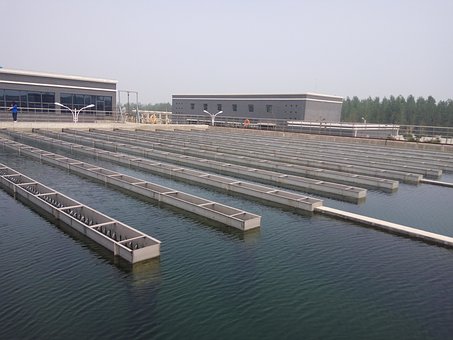

- Water purification plants

- Sewage treatment works

- Conveyors

- Large electric motors

- Railways

- Lifts/Elevators

- Glass container plants

- Chemical plants

- Laundry equipment

- Wood processing machinery

- Mechanical robotics

- Dockside equipment

- Ships

- Bakeries

- Brickworks

- Printers

SAFE FOR USE IN ANY INDUSTRY OR ENVIRONMENT

Due to the nature of its construction the GREASOMATIC is classified under the ATEX Directive 94/9/EC as not having its own ignition source. Furthermore it has been accepted for its suitability for use underground by CERBERUS (Mining Acceptance Services Ltd) as a single point lubricator.